(PDF) Selected Rolling Bearing Fault Diagnostic Methods in Wheel Embedded Permanent

A.P. Ompusunggu et al., - Automated bearing fault diagnostics with cost-effective vibration sen- sor 7 speeds of the second shaft are 609, 696, 783 an d 870 rpm, while the torques applied

Proposed method of bearing fault detection. Download Scientific Diagram

A novel diagnostics method that can deal with the high background noise of the sensor is presented and the results show that the diagnostics performance of the cost-effective accelerometer is comparable with the one of the high-end accelerometer. A non-continuous condition monitoring approach through periodic vibration measurement has become a common practice in the industry. However, this.

Sensors Free FullText Bearing Fault Diagnosis Using a Hybrid Fuzzy VStructure Fault

Rolling element bearings (REBs) are an essential part of rotating machinery. A localised defect in a REB typically results in periodic impulses in vibration signals at bearing characteristic frequencies (BCFs), and these are widely used for bearing fault detection and diagnosis. One of the most powerful methods for BCF detection in noisy signals is envelope analysis. However, the selection of.

60 60000r / Min Non Destructive Testing Equipment For Bearing Fault Detection Vibration

Bearing elements are vital in induction motors; therefore, early fault detection of rolling-element bearings is essential in machine health monitoring. With the advantage of fault feature representation techniques of time-frequency domain for nonstationary signals and the advent of convolutional neural networks (CNNs), bearing fault diagnosis has achieved high accuracy, even at variable.

(PDF) Deep Learning Algorithms for Bearing Fault Diagnostics A Comprehensive Review

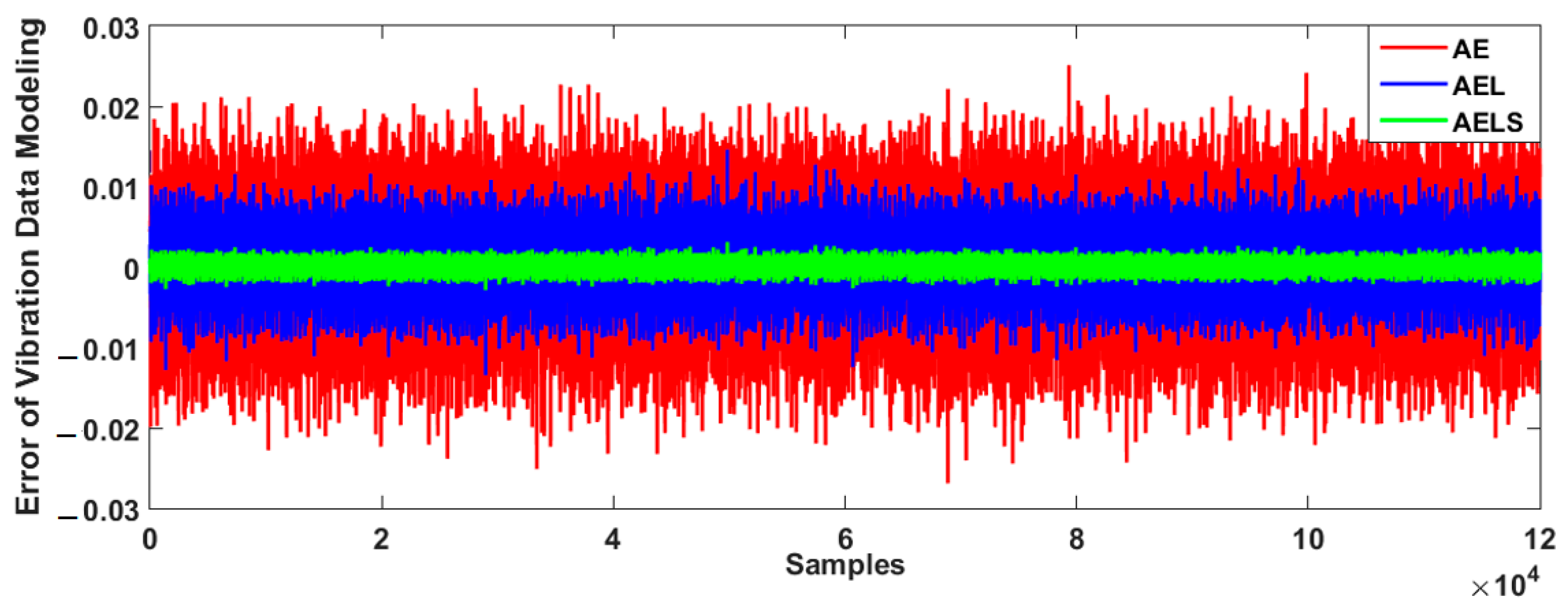

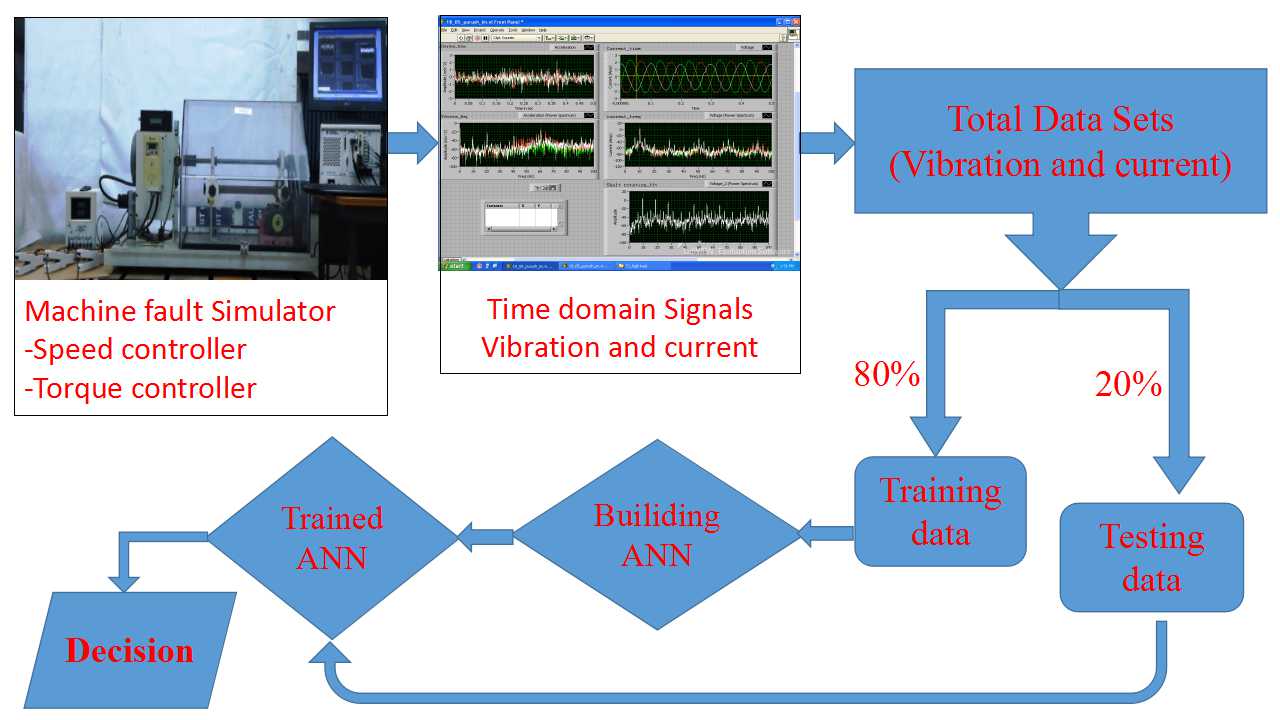

Vibration analysis is considered the most reliable and effective approach for monitoring the condition of rotating machinery. We present a reliable and accurate diagnosis of machine-bearing faults using vibration signals. The proposed method was validated using four datasets consisting of three motor conditions.

(PDF) A Lightweight and Deployable Bearing Fault Diagnosis Network via Decoupled

Automated fault diagnosis algorithms based on vibration sensor recordings play an important role in determining the state of health of the machines. Data-driven approaches demand a large amount of.

(PDF) Bearing Fault Diagnosis Based on Randomized Fisher Discriminant Analysis

A.P. Ompusunggu et al., - Automated bearing fault diagnostics with cost-effective vibration sen- sor 7 speeds of the second shaft are 609, 696, 783 and 870 rpm, while the torques applied

(PDF) Bearing Fault Diagnosis Using a Hybrid Fuzzy VStructure Fault Estimator Scheme

cost-effective vibration sensors inherently comprise some technical limitation, e.g. high background noise. These shortcoming needs to be solved before these sensors can be used in an industrial setting. This paper first discusses the selection of a cost-effective vibration sensor from the market and the sensor deployment for con-

(PDF) SelfAligned Bearing Fault Detection using Vibration Signals Analyzed by Spectrum Analysis

Ompusunggu, A.P., Ooijevaar, T., Kilundu, B., and Devos, S., 2019. Automated Bearing Fault Diagnostics with Cost-Effective Vibration Sensor, Proceedings of the 12th World Congress on Engineering Asset Management and the 13th International Conference on Vibration Engineering and Technology of Machinery.

(PDF) Bearing fault feature extraction based on optimized EMD by adaptive resonance

Gangsar et al. (2017) proposed an examination of current and vibration monitoring for effective defect estimate in induction motors (IM) by multiclass support vector machine (MSVM) methods.. "An automatic bearing fault diagnosis method based on characteristics frequency ratio," Sensors (Switzerland), vol. 20, no. 5, pp. 1-12, 2020.

(PDF) Rolling Bearing Fault Diagnosis Based on SVDGST Combined with Vision Transformer

Nondestructive monitoring techniques such as vibration and acoustic are two of the most used non-destructive monitoring techniques for bearing fault diagnosis. In recent years, different review studies have been carried out to detect the rolling bearing defects, their characteristics, and their analysis techniques such as the work presented by.

Sensors Free FullText Bearing Fault Diagnosis Using a Hybrid Fuzzy VStructure Fault

Three bearing fault datasets from three institutes, together with one readily available, was employed to validate the suggested model. Moreover, [205] suggested a transfer learning- CNN (TLCNN) for bearing fault diagnosis based on AlexNet. To transform a vibration signal into a two-dimensional time-frequency image, a two-dimensional image's.

(PDF) Bearing Fault Classification of Induction Motors Using Discrete Wavelet Transform and

Rolling element bearing (REB) vibration signals under variable speed (VS) have non-stationary characteristics. Order tracking (OT) and time-frequency analysis (TFA) are two widely used methods for REB fault diagnosis under VS. However, the effect of OT methods is affected by resampling errors and close-order harmonic interference, while the accuracy of TFA methods is mainly limited by time.

Sensors Free FullText A Bearing Fault Classification Framework Based on Image Encoding

Accurately identifying bearing defects is crucial for guaranteeing the dependability and effectiveness of industrial systems. Although the use of vibration signals for diagnosing bearing faults is highly important, there are still persistent obstacles, especially when it comes to detecting minor damage in the early stages. Relying solely on time-domain analysis for statistical feature.

(PDF) Wayside Bearing Fault Diagnosis Based on a DataDriven Doppler Effect Eliminator and

The key contributions of this paper are: •A simple yet effective CNN architecture that exhibits robustness in noisy and variable speed conditions. •A precise real-time diagnostic tool for various bearing faults that surpasses the current state-of-the-art technique [11] with a great margin; up to 15.8% gain in accuracy.

Artificial neural network based fault diagnostics for three phase induction motors under similar

Automated bearing fault diagnostics with cost-effective vibration sensor. In J. Mathew, C. Lim, & L. Ma (Eds.), Asset intelligence through integration and interoperability and contemporary vibration engineering technologies. proceedings of the 12th world congress on engineering asset management (pp. 463-472).

- Gas Natural Revision Anual Obligatoria

- Ama De Llaves O Camarera De Piso

- Pelicula Tormenta Por La Mañana Amor Por La Tarde

- Interview Questions And Answers Pdf

- Boletin Oficial Del Estado Ministerio De Defensa 2015

- Farmacia El Ventanal De La Sierra

- Parque Natural Sierra De María Los Vélez

- Rollo Corcho Adhesivo 50mm 2mm

- Cubic Feet Of A Hole Calculator

- Site De Rencontre Pour Seniors Gratuit