The seven (7) major applications of HACCP principles (Source Aruoma

Application manual: The manual explaining HACCP principles, its application to specific processes and products and the principal programme components required by control agencies (i.e. prerequisite control, hygiene control programme, generic HACCP model) is vital for successful application of HACCP by industry. The manual is an aid to the official inspection workforce and to management and.

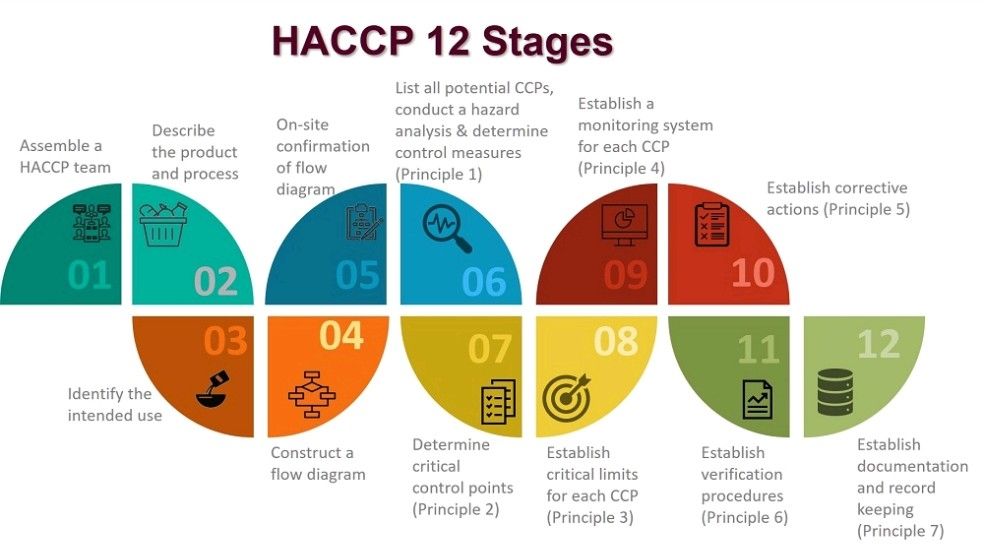

food and Health safety updates 12 Steps of HACCP

In Australia, HACCP is a legal requirement for all food and beverage companies. The Food Standards Australia New Zealand (FSANZ) has set out the requirements for HACCP in the Australia New Zealand Food Standards Code, which outlines the standards for food safety, labelling, and composition. The HACCP system involves seven principles: 1.

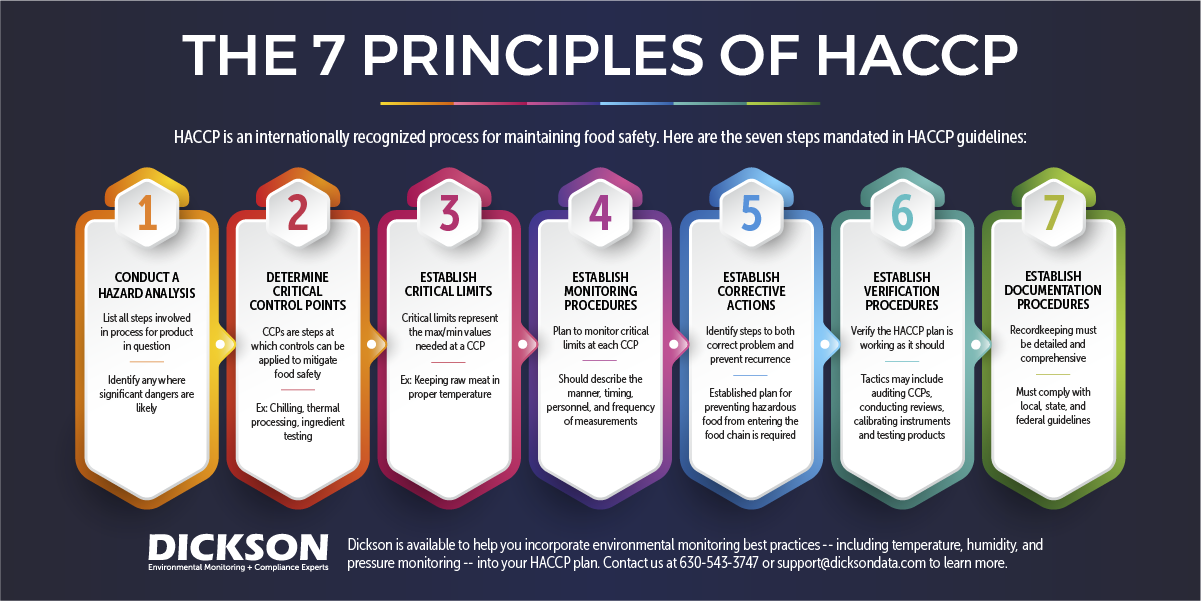

What are the 7 Principles of HACCP? Training Terminal

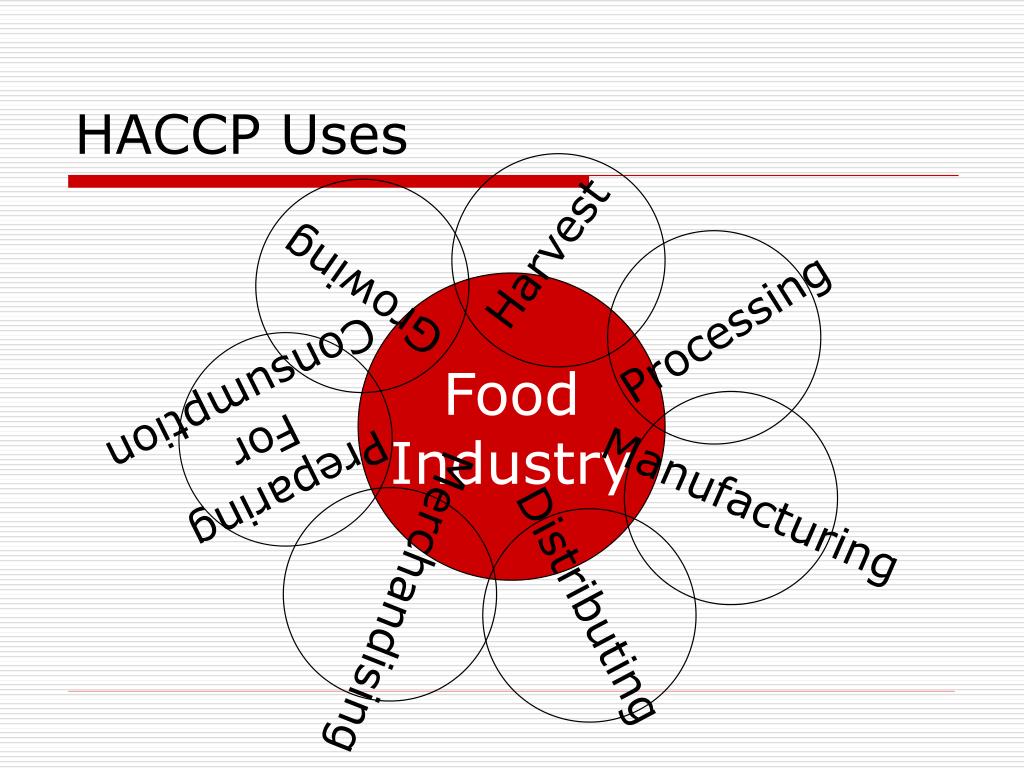

The application of HACCP to the food industry improves food safety, and it enhances the company's reputation in the community, especially export companies, by ensuring the product quality, establishing an excellent brand, and participating in international competition. Excellent monitoring and control mechanisms, and the completion of records.

The HACCP System Simplified Food Safety iHASCO

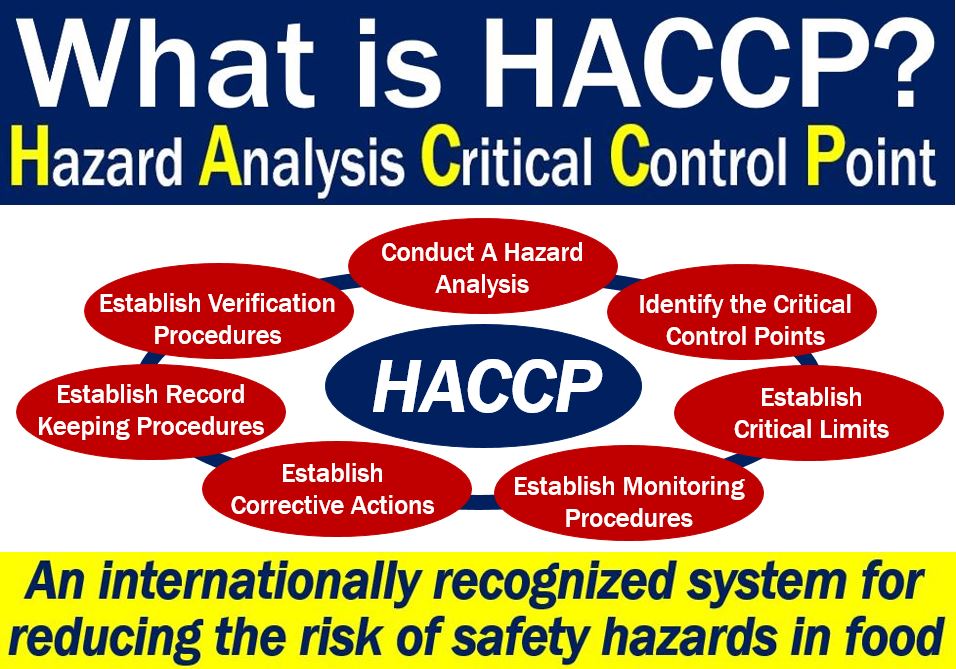

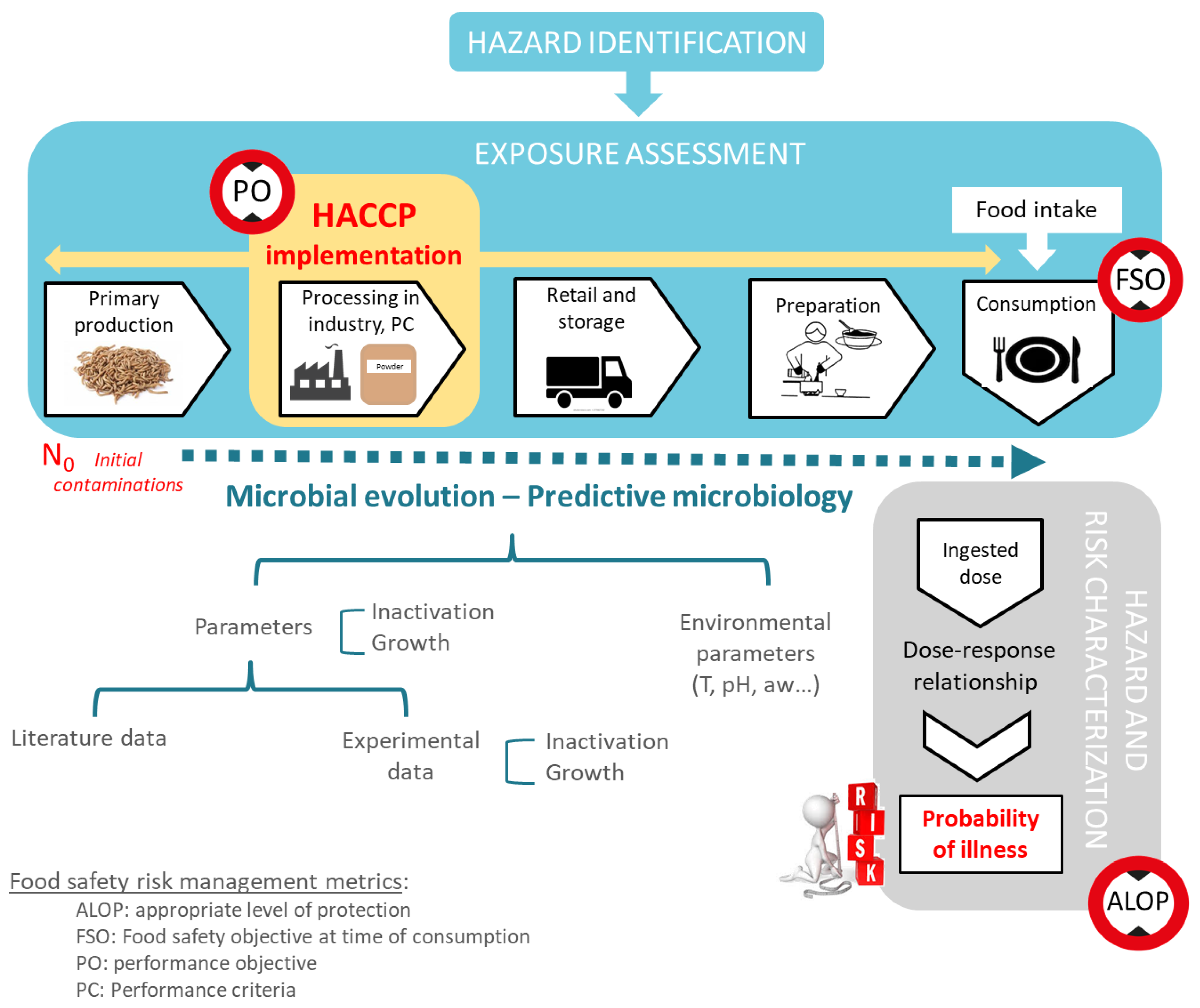

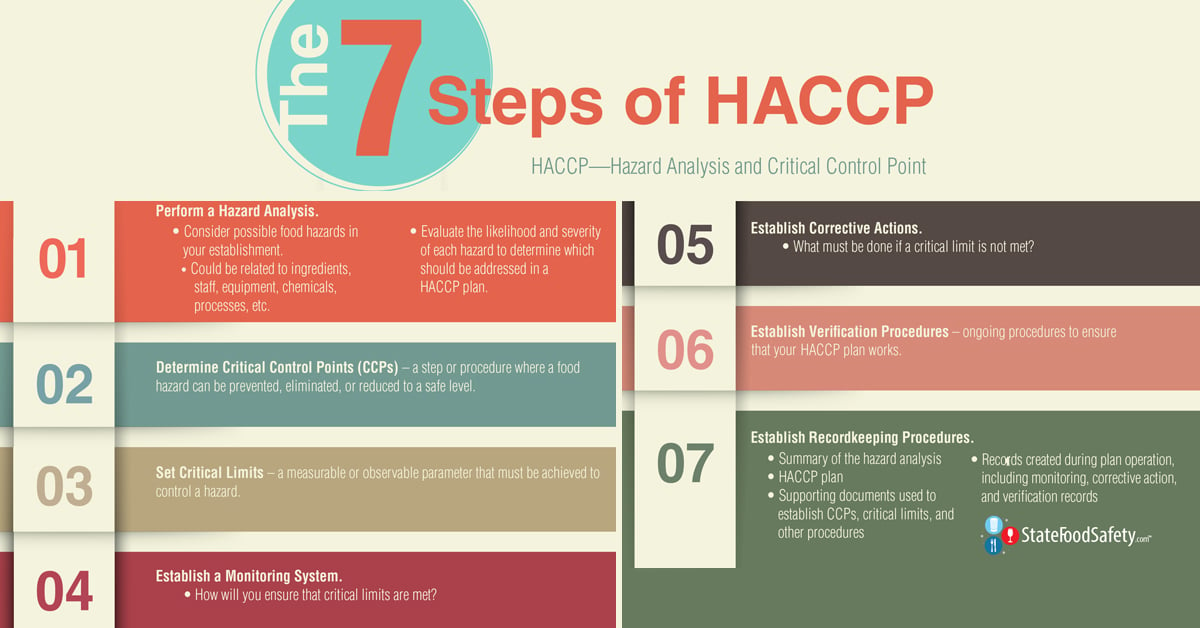

The food safety must be approached in a systemic way, by applying the seven basic principles of HACCP: (1) conduct a hazard analysis, (2) identify critical points, (3) establish control limits, (4) develop monitoring procedures, (5) establish corrective actions, (6) establish audit procedures, and (7) keep records [[19], [23]].The HACCP method forms the basis for various food safety management.

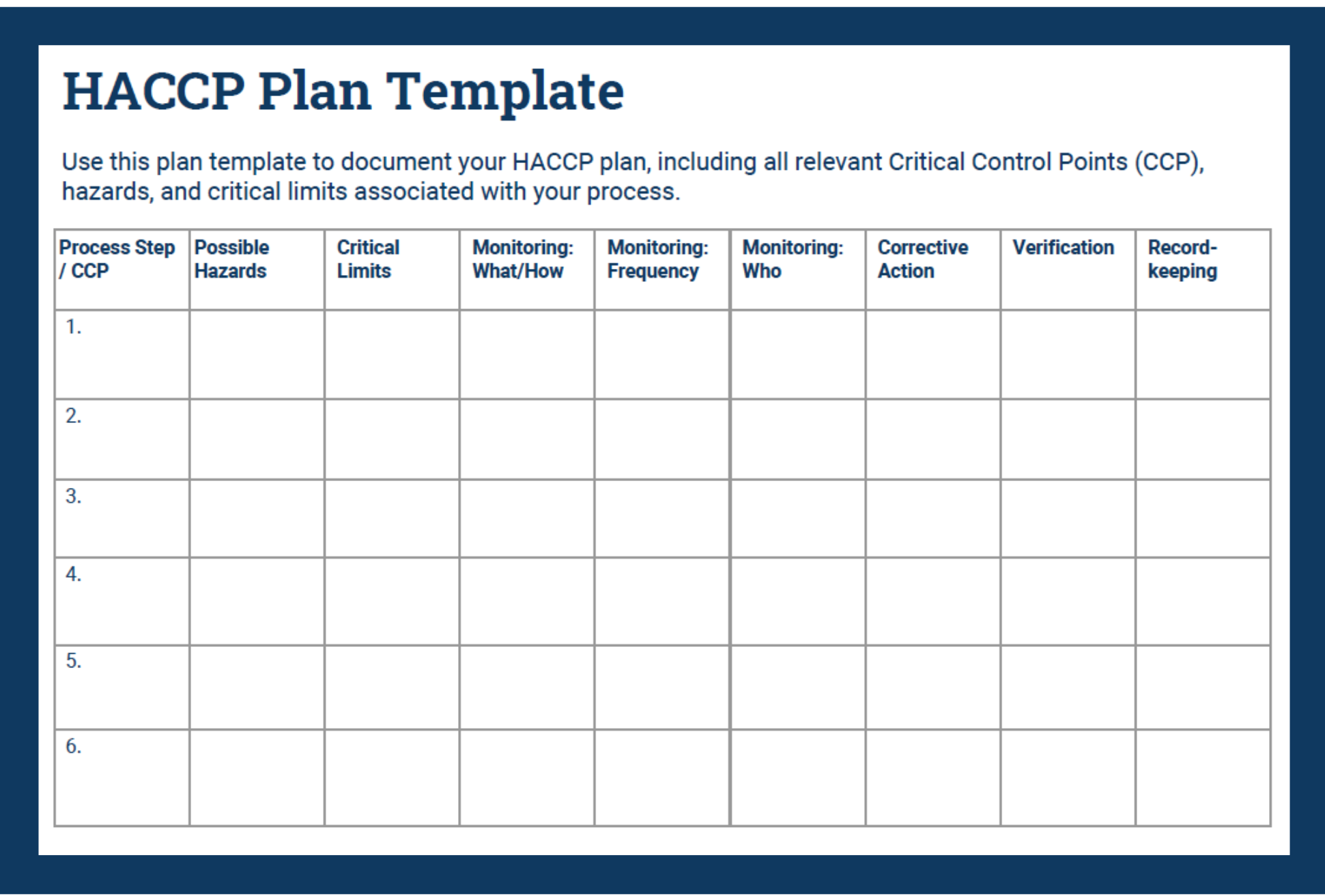

Creating a HACCP Plan What Your Organization Needs to Ensure Food Safety

HACCP is a scientific system for process control that has long been used in food production. It prevents food safety problems by applying controls at identified points in a food production process at whichhazards can be prevented, controlled, eliminated, or reduced to acceptable levels. An effective HACCP system includes: • A HACCP plan ;

Completing Your HACCP Plan Template a StepByStep Guide Safesite

By definition, HACCP is intended to control hazards, typically divided into physical, chemical, and biological hazards. In the context of the feed-food supply chain, the hazards to be considered fall into two main groups: (a) Hazards that have the potential to cause direct harm to animals eating feed products.

Haccp Plan Example Check more at

Standard 3.2.1 of the Food Standards Code ('the Code') enables: "States and Territories to require food businesses to implement a food safety program based upon the HACCP concepts. The food safety program is to be implemented and reviewed by the food business, and is subject to periodic audit by a suitably qualified food safety auditor."

PPT HACCP Approach to Food Safety PowerPoint Presentation, free

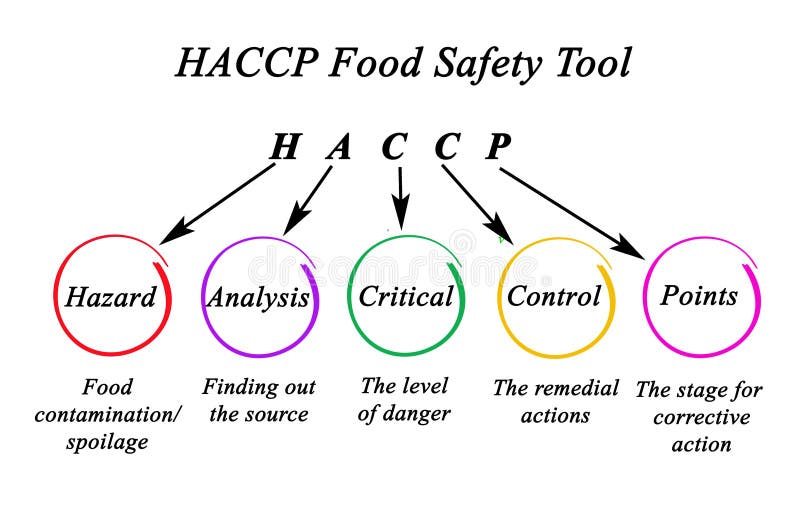

HACCP stands for the hazard analysis and critical control point system. Today, it is known more by its acronym than its full name. HACCP as defined by the Codex Alimentarius Commission is a system that identifies, evaluates, and controls hazards which are significant for food safety (CAC (Codex Alimentarius Commission), 2003).Worldwide, it is considered as the reference method for food safety.

Haccp Food Safety Plan Template Luxury 28 Of Haccp Plan Template Flow

Food safety hazards are biological, chemical or physical agents that are reasonably likely to cause illness or injury in the absence of their control. A HACCP system is a preventive system of.

Training Tip HACCP Plans Food safety, Food safety tips, Food safety

1. Conduct a hazard analysis. The first step of implementing the HACCP in the workplace is to undertake a hazard analysis of the environment. Hazards, in this context, are potential safety concerns that could occur at any stage of your food processing production process - and they may be physical, biological or chemical hazards.

HACCP definition and meaning Market Business News

HACCP is a scientific system to identify, monitor, and control contamination risks in food industry. This book addresses the demands of the hotel industry in the new millennium.

Haccp Plan Template Food safety, How to plan, Food safety and sanitation

HACCP - introduction. HACCP is an important part of food safety management. It is a globally recognized, systematic and science-based approach to food safety that addresses biological, chemical and physical hazards throughout the food chain from primary production to final consumption. The HACCP approach focuses on control measures for.

HACCP Food Safety Tool stock illustration. Illustration of haccpfood

The burden of foodborne diseases and their associated illness/death is a global concern. Hazard analysis and critical control points (HACCP) and food safety/quality management are employed to combat this problem. With the existing and emerging food safety/quality management concerns, this study aims to evaluate the traditional and modern/novel.

Foods Free FullText Control of Biological Hazards in Insect

To find out if you need a food safety program for your business visit the industry sectors. Food safety programs are based on Codex Alimentarius Commission's HACCP system and guidelines, or Standard 3.2.1 of the Food Standards Code. HACCP stands for Hazard Analysis and Critical Control Point. Food safety programs:

Specialized Food Processes (HACCP) Boulder County

HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to processing, distribution and consumption of the finished product. Preventing problems from occurring is the paramount goal underlying any HACCP.

Control Critical Food Safety Points in Your Restaurant with HACCP

HACCP is a systematic preventive approach to food safety. It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe. By controlling these hazards, it minimizes the risk of foodborne illnesses. HACCP is a fundamental component of food safety management.

- Telefono Oficinas Futbol Club Barcelona

- Km De Madrid A Aldea Nueva De La Vera

- Modelo De Carta De Terminacion De Contrato De Arrendamiento

- Bar Baster Bilbao Edificio Racionalist

- Además De Ser Una Experiencia En Frances

- Ronda Rousey Vs Ebanie Bridges

- Manual De Limpieza De Un Monje Budista Gratis

- Cuanto Cuesta Un Huevo De Tortuga

- Crema Facial Para Las Manchas Dela Cara

- Lexus Rc F Rear Spoiler